The transfer of ceramics technology from China to Korea and Japan between the years of 600 AD and 1900 AD was a complex and long-lasting process. It was influenced by a variety of factors, including trade, diplomacy, and religious exchanges.

Clay Materials

Chinese potters used a variety of clay materials, including kaolin, feldspar, and quartz. Kaolin is a high-quality clay that is white and fine-grained. It is used to produce white porcelain. Feldspar and quartz are used to produce stoneware and celadon.

Korean and Japanese potters adopted the use of Chinese clay materials. However, they also developed their own unique clay bodies. For example, Korean potters developed a clay body called buncheong, which is known for its gray color and speckled glaze. Japanese potters developed a clay body called raku, which is known for its red color and porous texture.

Glazes

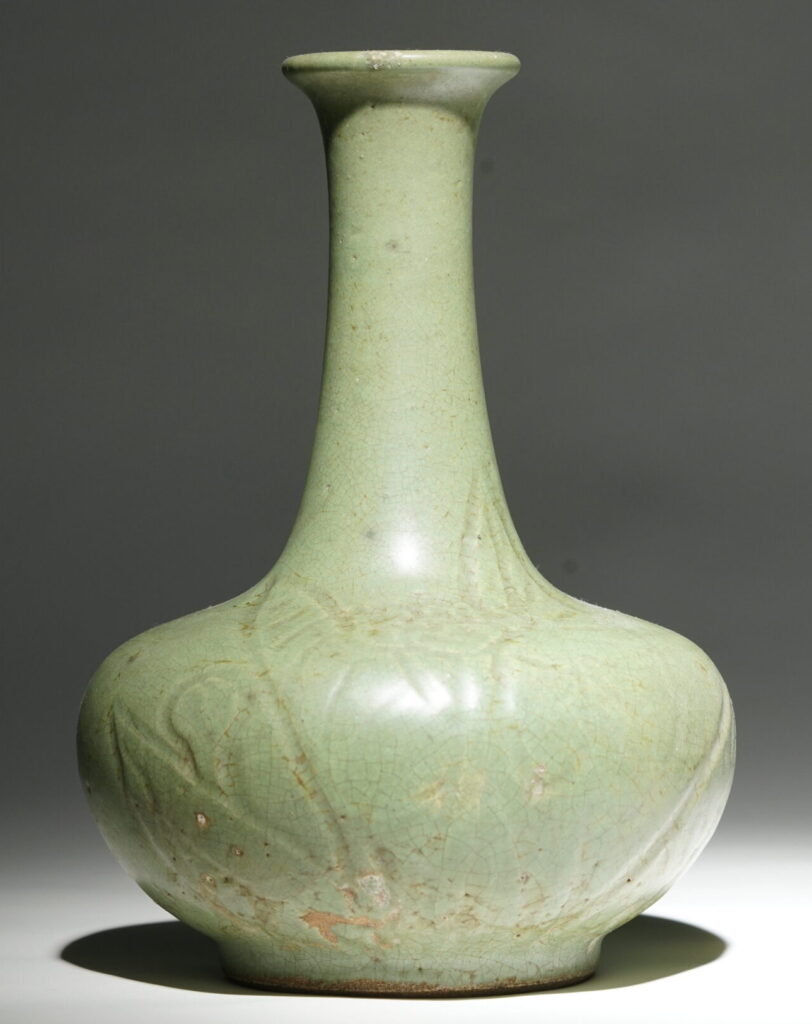

Chinese potters developed a variety of glazes, including lead glazes, ash glazes, and felspathic glazes. Lead glazes are clear and transparent. They are used to produce white porcelain and celadon. Ash glazes are opaque and milky. They are used to produce stoneware. Felspathic glazes are clear and transparent. They are used to produce high-fired stoneware and porcelain.

Korean and Japanese potters adopted the use of Chinese glazes. However, they also developed their own unique glazes. For example, Korean potters developed a glaze called injae, which is known for its blue color and craquelé pattern. Japanese potters developed a glaze called temmoku, which is known for its iron-black color and iridescent sheen.

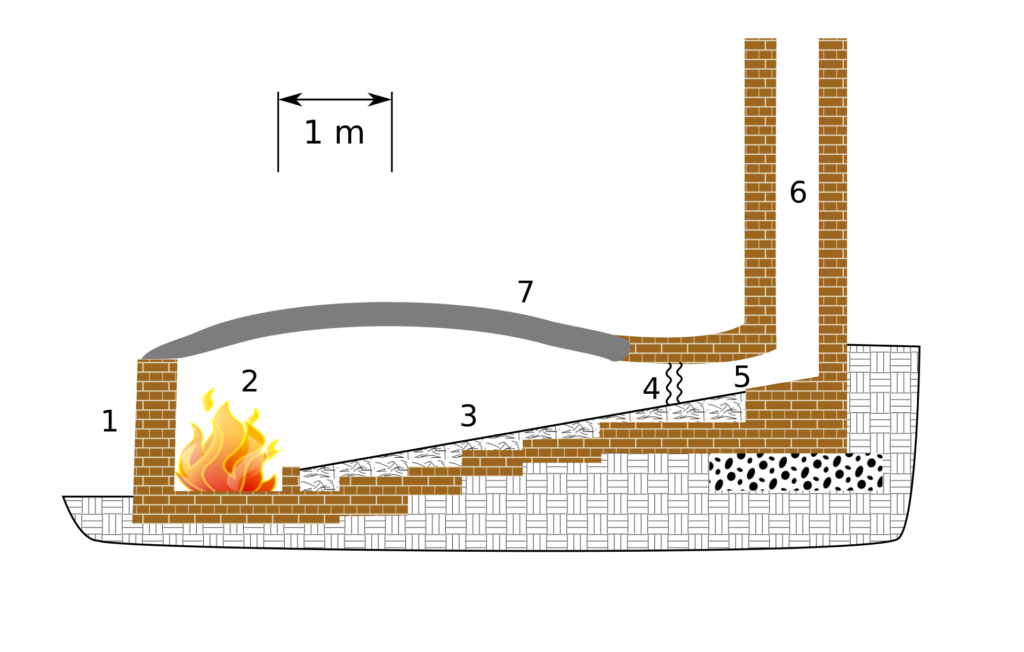

Kiln Technology

Chinese potters used a variety of kiln technologies, including dragon kilns, updraft kilns, and downdraft kilns. Dragon kilns are long and narrow kilns that can fire large quantities of pottery. Updraft kilns are smaller and simpler than dragon kilns. Downdraft kilns are the most advanced type of kiln. They can produce high temperatures and are used to fire high-fired stoneware and porcelain.

Korean and Japanese potters adopted the use of Chinese kiln technologies. However, they also developed their own unique kiln designs. For example, Korean potters developed a kiln called a saggama, which is known for its unique shape and high efficiency. Japanese potters uses a kiln called an anagama, which is known for its ability to produce high temperatures.

Artistic Styles

Chinese potters developed a variety of artistic styles, including blue-and-white porcelain, celadon, and sancai pottery. Blue-and-white porcelain is decorated with a cobalt blue glaze on a white background. Celadon is a type of pottery that is glazed in a green color. Sancai pottery is decorated with three colors: green, yellow, and brown.

Korean and Japanese potters adopted the use of Chinese artistic styles. However, they also developed their own unique styles. For example, Korean potters developed a style called buncheong, which is known for its simple and elegant designs. Japanese potters developed a style called wabi-sabi, which is known for its emphasis on the beauty of imperfection.